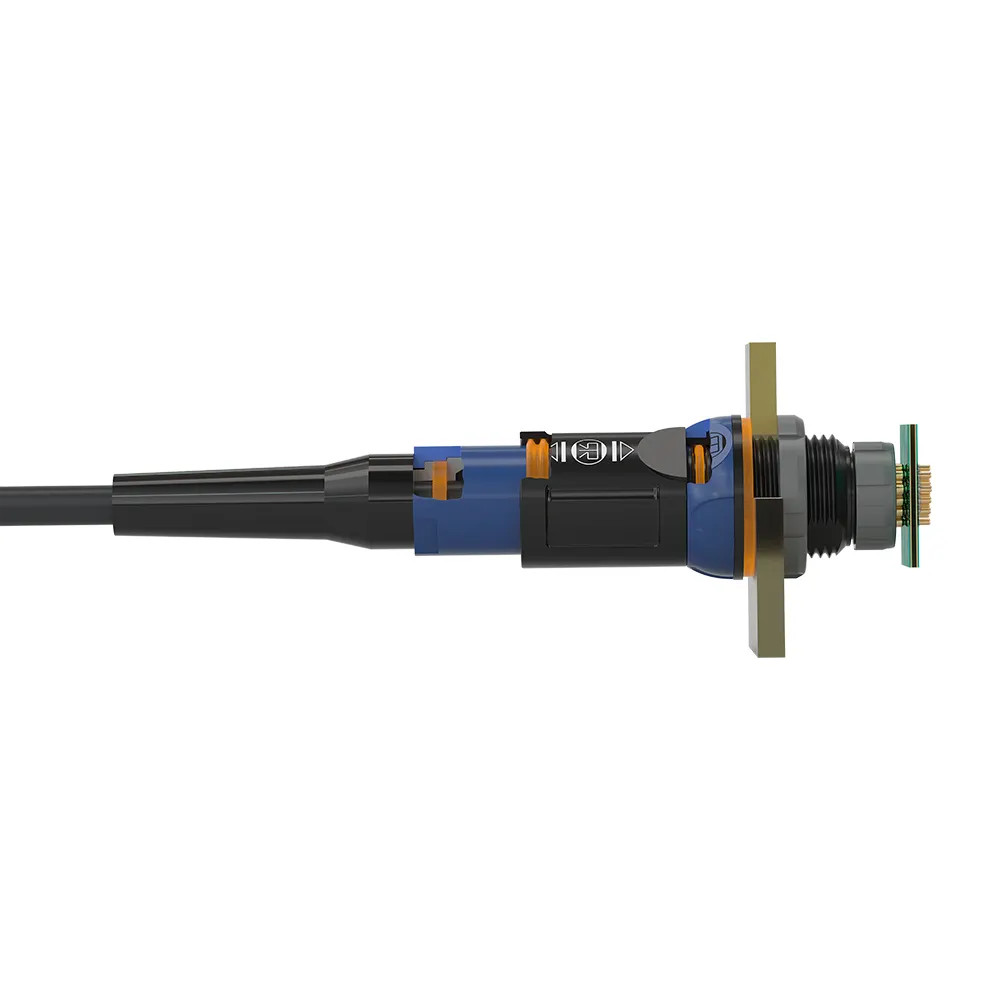

LEMO has officially released the new IP68‑rated version of its REDEL SP Series, delivering a major leap forward in sealed push‑pull connectivity for medical, industrial, test & measurement, and UAV applications. This next‑generation connector brings resin‑free IP68 sealing, higher robustness, and improved ease of assembly — all while maintaining the familiar lightweight ergonomics of the original SP platform.

Solving a persistant issue

Until now, achieving full IP68 sealing with many plastic circular connectors required potting resins or additional sealing compounds. The new REDEL SP IP68 eliminates that step entirely, using a resin‑free collet sealing system that provides a fully watertight mated connection to 2 metres for 2 hours.

This simplifies compliance, reduces assembly time, and prevents the compatibility issues that potting materials can introduce — a major win for medical and mission‑critical equipment designers.

Key Technical Highlights

1. Resin‑Free IP68 Sealing

The SP Series now achieves a fully dustproof and watertight IP68 seal with no resins required, relying instead on an engineered internal sealing structure.

This design ensures:

- Greater reliability

- Cleaner assembly workflow

- Better repeatability

- Compatibility with sterilisation processes

2. High‑Density Connectivity in a Compact Footprint

Despite the ruggedized IP68 sealing, the connectors remain compact at Ø15.5 mm and support up to 22 contacts, retaining one of the highest density‑to‑size ratios in the market.

This makes them ideal for:

- Surgical instruments

- Diagnostic equipment

- Portable field instruments

- UAVs and robotics

3. FDA‑Certified PPSU Construction

The SP IP68 housings are made from PPSU (polyphenylsulfone) — lightweight, extremely durable, and resistant to harsh disinfectants, repeated sterilisation, and chemicals.

This material choice enables:

- Autoclave compatibility

- High‑temperature resistance

- Long‑term mechanical strength

4. Patented Internal Push‑Pull Latching

LEMO’s internal push‑pull system provides secure, ergonomic mating while improving shock resistance and preventing accidental disconnection.

5. Reinforced Mechanical Shock Resistance

Mechanical robustness has been enhanced for demanding environments, supporting both medical and industrial usage.

Improved Workflow for OEM Designers

With the SP IP68, LEMO supports fully sealed cable assemblies using its BioCompatic® medical‑grade cables, which maintain IP68 integrity, sterilisation resistance, and signal performance.

Assemblies are manufactured under ISO 13485 processes, enabling medical OEMs to integrate pre‑qualified, regulation‑compliant harnesses directly into their devices.

Applications That Benefit Most

The new REDEL SP IP68 targets environments where fluid ingress, cleaning cycles, or contamination risks make traditional connectors unsuitable:

- Medical devices (endoscopy, patient monitoring, surgical robotics)

- Laboratory and test & measurement systems

- Industrial automation

- Unmanned systems (UAVs, drones)

- Portable field electronics

Its combination of lightweight PPSU, high contact density, and proven push‑pull reliability makes it one of the most versatile IP68‑rated plastic circular connectors available today.

Whether you’re designing next‑generation medical equipment or rugged field instrumentation, the new IP68 SP Series offers unmatched reliability, usability, and compliance.