In industries where safety, precision, and uptime are critical, Non‑Destructive Testing (NDT) is the backbone of asset integrity. As inspection demands grow more complex, technicians need smarter, faster, and more reliable tools than ever before.

evoSonic, founded by technicians who understand real field conditions, is reshaping the global NDT landscape by designing inspection systems that are not just advanced—but practical, rugged, and built for real‑world workflows. The company openly states that many traditional NDT devices “don’t quite fit the challenges of the field,” which is why they set out to close this gap through user‑driven innovation.

With roots in both Australia and the United States, evoSonic brings global experience to industries such as oil and gas, mining, subsea, defence, and infrastructure maintenance. Their mission is bold: to drive the inspection evolution through smarter technology, better accuracy, and real‑time field intelligence.

Closing the Gap Between Technician Needs and Technology

Field technicians often face a difficult trade‑off between speed, accuracy, ergonomics, and data quality — and even the most advanced NDT technology cannot perform at its full potential without equally reliable, high‑integrity connections. evoSonic eliminates this compromise by pairing their intelligent inspection systems with LEMO Harsh‑Environment T‑Series connectors, renowned for exceptional reliability in demanding industrial conditions such as those found in pipeline, refinery, and field inspection environments. These connectors deliver secure Push‑Pull latching and robust environmental sealing, supporting the kind of high‑resolution data integrity that advanced PAUT and UT tools require.

This combination of evoSonic technology and LEMO connectivity enables significant real‑world performance gains. Operators across major asset owners — including Kinder Morgan, Santos, and ExxonMobil — have reported substantial increases in productivity, reductions in manual layout and marking, and major improvements in scan accuracy. In one example, inspection rates jumped from approximately 50–60 metres per day to nearly 200 metres, demonstrating the direct operational impact of pairing advanced instrumentation with reliable, harsh‑environment connectors.

This level of reliability — in both tools and their connections — is what drives the kind of efficiency shift that transforms operational safety, extends asset lifespan, and fundamentally reshapes budget planning.

Innovation That Moves the Industry Forward

evoSonic’s product ecosystem is built on deep field knowledge, high-end engineering, and fast iteration cycles. Three core technologies highlight their approach:

evolutionONE — A New Benchmark in Portable Phased Array

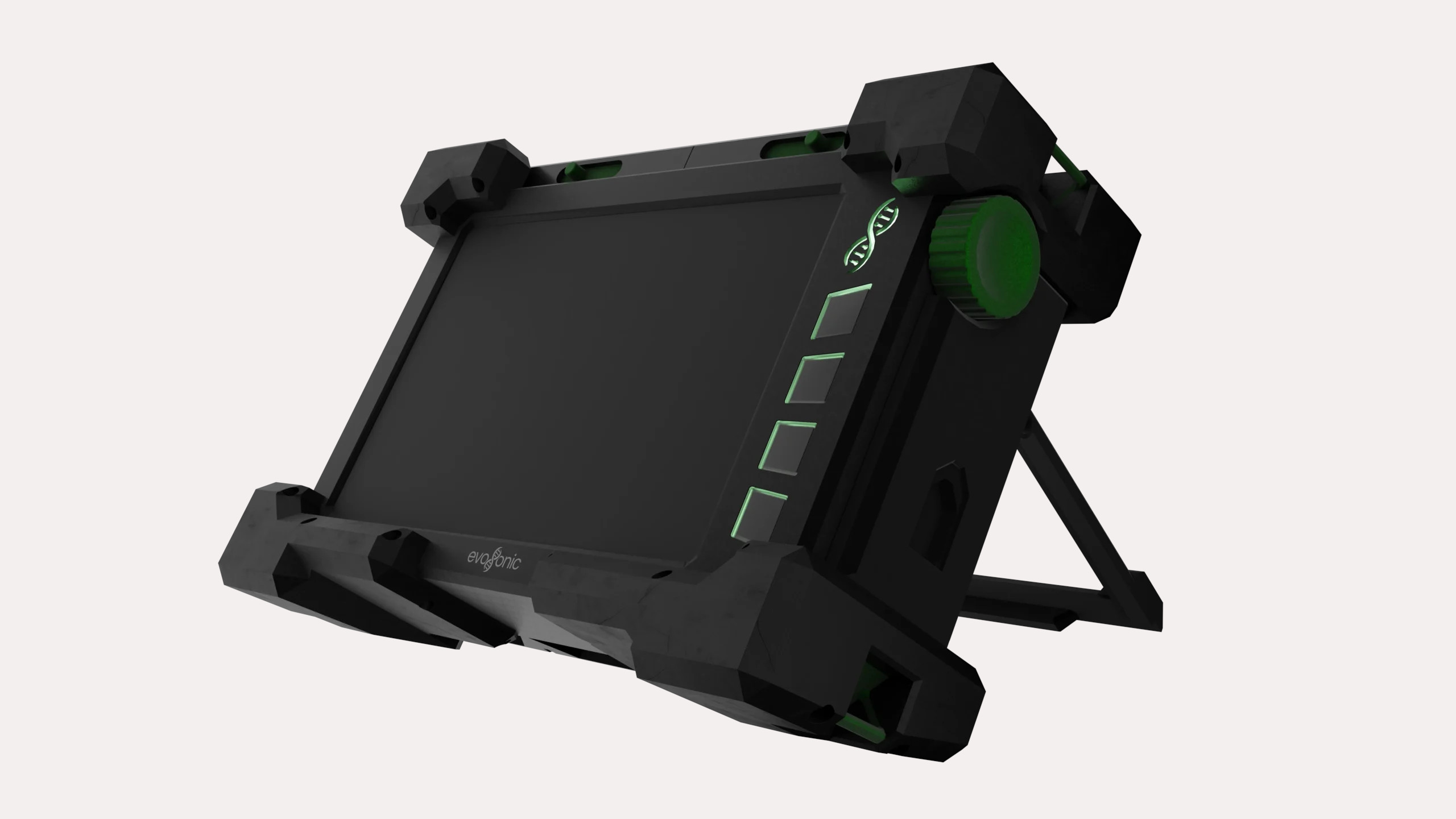

Launching in March 2026, the evolutionONE represents a major leap in portable phased-array ultrasonic testing (PAUT). It introduces:

Advanced file compression that transfers large datasets in seconds, not hours

True 16‑bit architecture for enhanced signal-to-noise performance

Real‑time capture and processing for crisp, accurate imaging

Patent‑pending TrueSignal™ technology that optimises SNR and amplitude fidelity

This platform offers lab‑grade capability in a rugged, portable form factor—ideal for technicians in the field.

evoARC — The World’s First Contactless Encoder

At the core of accurate scanning is motion tracking—and evoARC solves an age‑old problem: wheel traction. evoARC uses contactless encoding to ensure repeatable, accurate scans, even on irregular surfaces. This innovation has drawn strong endorsements from operators looking to minimise human error and accelerate NDT workflows.

evoDUAL — Compact Dual‑Axis Inspection Power

Launched in 2025, the evoDUAL brings dual‑element and single‑element ultrasonic inspection into one compact tool. It provides:

- Dual‑axis scanning for high‑resolution flaw detection

- A simple, intuitive interface

- Miniaturised, rugged industrial design

- Compatibility with Evident’s REX1-DLA for advanced imaging

CEO Kimal Singh summed up evoSonic’s vision clearly:

“We’re not just building tools. We’re rethinking how inspections are done.”

Confidence in Every Connection: The solution is LEMO

High‑performance inspection demands high‑performance connectivity. evoSonic integrates LEMO Push‑Pull connectors across its systems to ensure:

- Unshakeable mechanical security with LEMO’s iconic Push‑Pull latching

- Superior signal integrity for a clean, reliable data path—critical for PAUT and UT

- Environmental resilience, including vibration resistance, ingress protection, and longevity

- Fast, error‑free connection cycles in field conditions, even when technicians are wearing gloves

LEMO connectors are renowned globally for their precision engineering and reliability across medical, industrial, test-and-measurement, and broadcast applications.

Using LEMO connectors ensures that every scan, every signal, and every data transfer maintains the integrity needed for asset-critical decision making. When the cost of failure is high, the connector simply cannot be a weak point—and with LEMO, it isn’t.

Driving the Future of Industrial Integrity

With technician‑driven design, fast-growing global traction, and a vision to lead the evolution of inspection by 2030, evoSonic is setting a new standard for safety and productivity in modern NDT.

Pairing their advanced technologies with LEMO’s world‑class connectivity delivers a powerful combination.

speed, confidence, and absolute reliability.

This is the next era of NDT—and evoSonic is already living it.